How to clean up spills of Sodium Metaaluminate Liquid safely?

Jun 24, 2025

Hey there! As a supplier of Sodium Metaaluminate Liquid, I've seen my fair share of spills. It can be a real headache, but with the right approach, you can clean it up safely. In this blog, I'll share some tips and tricks on how to handle these spills like a pro.

Understanding Sodium Metaaluminate Liquid

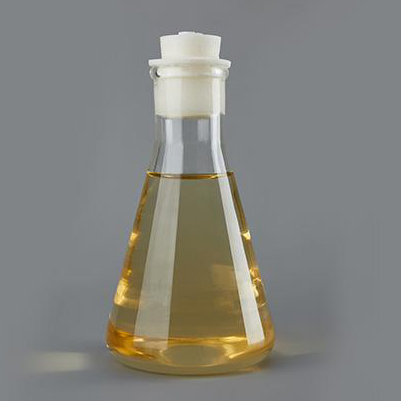

First off, let's talk a bit about what Sodium Metaaluminate Liquid is. It's a highly alkaline substance that's used in a bunch of industries. You can find it in products like Sodium Aluminate for Molecular Sieve, 37% Concentration Of Sodium Metaaluminate, and Sodium Metaaluminate for White Carbon Black. Due to its alkaline nature, it can cause skin burns, eye damage, and other health issues if it comes into contact with you. So, safety is super important when dealing with spills.

Safety First: Preparing for Cleanup

Before you even think about cleaning up a spill, you need to gear up. Put on the right personal protective equipment (PPE). This includes safety goggles to protect your eyes from any splashes, chemical-resistant gloves to keep your hands safe, and a full-body apron or suit to prevent the liquid from touching your skin. You should also have a pair of closed-toe shoes on to protect your feet.

Make sure the area is well-ventilated. Open windows and doors if you're indoors, or if it's an outdoor spill, make sure there's good air circulation. This helps to prevent the inhalation of any fumes that might be released from the spill.

If there are other people around, clear the area. Let them know there's a spill and keep them at a safe distance until it's cleaned up. You don't want anyone accidentally stepping in the spill or getting exposed to the chemical.

Containing the Spill

Once you're all suited up and the area is safe, it's time to contain the spill. This stops it from spreading further and causing more damage. You can use absorbent materials like sand, vermiculite, or commercial spill kits. These materials soak up the liquid and make it easier to clean up.

Start by pouring the absorbent material around the edges of the spill. This creates a barrier that stops the liquid from flowing out. Then, gradually add more absorbent material to the center of the spill until it's completely covered. Let it sit for a few minutes to allow the absorbent to do its job.

Cleaning Up the Spill

After the spill is contained, it's time to clean it up. Use a shovel or a scoop to collect the absorbent material along with the soaked-up Sodium Metaaluminate Liquid. Put it into a suitable container, like a plastic drum or a metal bin. Make sure the container is labeled properly so that everyone knows what's inside.

Once you've collected all the absorbent material, use a damp cloth or a sponge to wipe down the area where the spill occurred. Make sure you use water that's been treated with an acid to neutralize any remaining traces of the alkaline chemical. You can use a weak acid like acetic acid (vinegar) for this purpose.

Rinse the area thoroughly with clean water to make sure all the chemical and the cleaning agents are removed. Check the area carefully to make sure there are no remaining traces of the spill.

Disposing of the Waste

Proper waste disposal is crucial. The collected absorbent material and any other waste from the cleanup are considered hazardous waste. You can't just throw them in the regular trash. Contact your local environmental protection agency or a hazardous waste disposal company to find out the proper way to dispose of it.

They'll give you instructions on how to package the waste and where to take it. Follow their guidelines carefully to avoid any legal issues and to protect the environment.

Post-Cleanup Checks

After the spill is cleaned up, it's a good idea to do some post-cleanup checks. Check your PPE for any signs of damage. If your gloves or apron have been contaminated, dispose of them properly.

Inspect the area where the spill occurred for any signs of corrosion or damage. If you notice any, take appropriate action to repair it. You might need to repaint a surface or replace a damaged floor tile.

Preventing Future Spills

Of course, the best way to deal with spills is to prevent them from happening in the first place. Make sure your storage areas are properly designed and maintained. Store Sodium Metaaluminate Liquid in sturdy containers that are labeled clearly. Keep them in a cool, dry place away from direct sunlight and other incompatible chemicals.

Train your employees on proper handling procedures. Teach them how to lift and move containers safely, how to use the chemical properly, and what to do in case of a spill. Regularly inspect your storage areas and equipment for any signs of leaks or damage.

Conclusion

Cleaning up spills of Sodium Metaaluminate Liquid safely is all about being prepared, taking the right precautions, and following the proper procedures. By understanding the chemical, using the right PPE, containing the spill, cleaning it up properly, and disposing of the waste correctly, you can minimize the risks and keep your workplace safe.

If you're in the market for high-quality Sodium Metaaluminate Liquid for your business, we're here to help. We offer a range of products that meet the highest industry standards. Whether you need Sodium Aluminate for Molecular Sieve, 37% Concentration Of Sodium Metaaluminate, or Sodium Metaaluminate for White Carbon Black, we've got you covered. Get in touch with us to discuss your requirements and start a purchase negotiation.

References

- "Safety Data Sheet for Sodium Metaaluminate Liquid"

- Industry guidelines on chemical spill cleanup and hazardous waste disposal