How does the agitation speed affect the dispersion of Liquid Sodium Metaaluminate in solutions?

Jul 09, 2025

Hey there! As a supplier of Liquid Sodium Metaaluminate, I've been getting a lot of questions lately about how agitation speed affects the dispersion of this compound in solutions. So, I thought I'd dive into this topic and share some insights based on my experience in the industry.

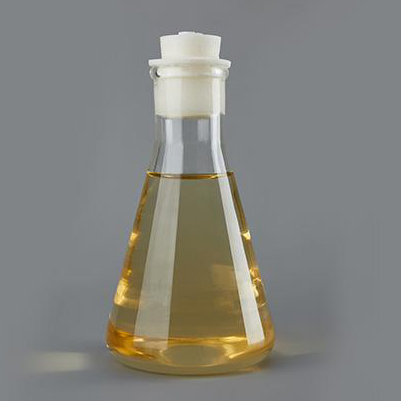

First off, let's quickly understand what Liquid Sodium Metaaluminate is. It's a versatile chemical that finds its use in various industries, such as water treatment, paper manufacturing, and the production of molecular sieves. Sodium Aluminate for Molecular Sieve is one of its popular applications, where it plays a crucial role in the synthesis process.

Now, let's talk about dispersion. Dispersion refers to how evenly the Liquid Sodium Metaaluminate is distributed throughout the solution. A well - dispersed solution ensures that the chemical can perform its intended function effectively. And agitation speed is a key factor that can significantly influence this dispersion.

When we start with a low agitation speed, the mixing process is relatively gentle. At this stage, the Liquid Sodium Metaaluminate may start to dissolve in the solution, but the dispersion is often uneven. The compound tends to clump together in some areas, and there might be pockets where the concentration is higher than others. This can lead to inconsistent results in the processes where the solution is used. For example, in water treatment, uneven dispersion of Liquid Sodium Metaaluminate can result in ineffective flocculation, meaning that impurities in the water may not be properly removed.

As we increase the agitation speed, things start to change. The increased force generated by the agitation helps to break up those clumps of Liquid Sodium Metaaluminate. The molecules of the compound are more actively mixed with the solvent, leading to a more uniform distribution. In a solution with a higher agitation speed, the chances of having concentration gradients are reduced, and the overall quality of the dispersion improves.

However, there's a catch. If we increase the agitation speed too much, we can run into other problems. High - speed agitation can create a lot of turbulence in the solution. This turbulence can cause the formation of air bubbles, which can have a negative impact on the dispersion. These bubbles can act as barriers, preventing the proper mixing of the Liquid Sodium Metaaluminate and the solvent. Moreover, excessive agitation can also lead to the degradation of the compound itself. The high - energy forces can break the chemical bonds in the Liquid Sodium Metaaluminate, altering its chemical properties and reducing its effectiveness.

Another aspect to consider is the concentration of the Liquid Sodium Metaaluminate in the solution. For instance, 37% Concentration Of Sodium Metaaluminate may require a different agitation speed compared to a lower - concentration solution. A higher - concentration solution is generally more viscous, and it might need a higher agitation speed to achieve good dispersion. But again, we have to be careful not to over - agitate.

In industries like the production of titanium dioxide, Sodium Metaaluminate for Titanium Dioxide is used as a modifier. The dispersion of this compound in the solution can affect the quality and properties of the final titanium dioxide product. If the Liquid Sodium Metaaluminate is not well - dispersed, it can lead to variations in the particle size and surface properties of the titanium dioxide, which can ultimately impact its performance in applications such as paints and coatings.

So, how do we find the optimal agitation speed? It's not a one - size - fits - all answer. It depends on several factors, including the concentration of the solution, the type of solvent used, and the specific application of the solution. One way to determine the optimal speed is through experimentation. We can start with a range of agitation speeds and measure the dispersion quality of the Liquid Sodium Metaaluminate in each case. This can be done using techniques like light scattering or microscopy to analyze the distribution of the compound in the solution.

Based on my experience, a good starting point for most applications is to begin with a moderate agitation speed and gradually adjust it up or down depending on the observed dispersion. If the dispersion is poor, we can increase the speed slightly. If we notice issues like air bubble formation or degradation of the compound, we should reduce the speed.

In conclusion, agitation speed has a complex relationship with the dispersion of Liquid Sodium Metaaluminate in solutions. Finding the right balance is crucial to ensure that the compound can perform its function effectively in various industries. Whether you're involved in water treatment, paper manufacturing, or the production of high - tech materials, getting the dispersion right can make a big difference in the quality of your final product.

If you're in the market for high - quality Liquid Sodium Metaaluminate and want to discuss how to optimize its use in your processes, feel free to reach out. We're here to help you get the most out of our product and ensure that your operations run smoothly.

References

- General knowledge of chemical engineering principles related to mixing and dispersion.

- Industry - specific research on the use of Liquid Sodium Metaaluminate in different applications.